STONE CHIP COATING LINE

1. BASE GLUE SPRAY CABINET

1.1 SIZE : 4000*1650*2000 (L*W*H)

1.2 RACK STRUCTURE: WELDED STRUCTURE OF STEEL PROFILES

1.3 Power: 380v/220v、50~60 Hz;

1.4 OPERATION SPEED: 4~10S/TILE

1.5 CONTROL: CVT AUTOMATIC CONTROL VIA PLC

1.6 BASE GLUE SPRAY: RECIPROCATING SPAY OPERATED BY PNEUMATIC AIRLESS SPAYER AND A STEPPING MOTOR

1.7 DEDUST APPLIANCE: ADSORPTION DUCT COLLECTOR.

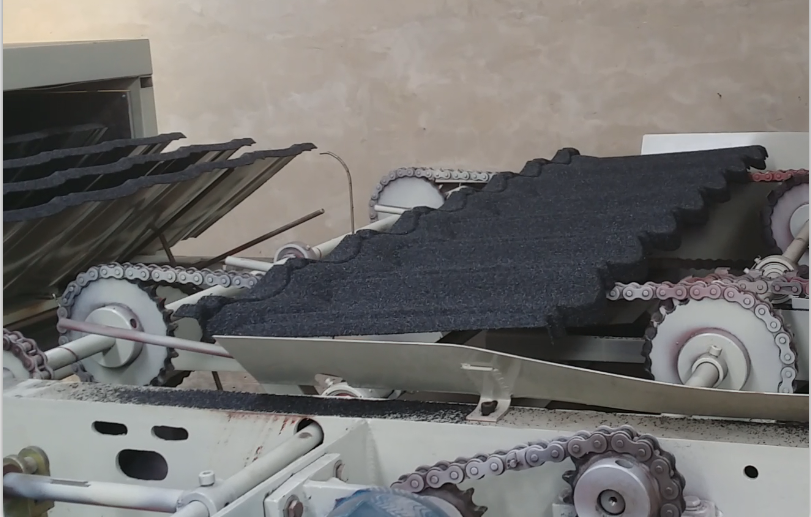

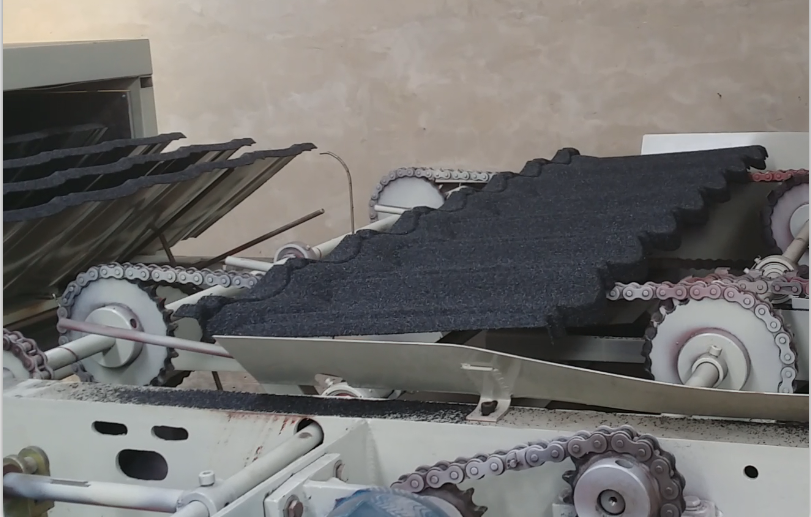

2. AUTOMATIC STONE CHIP COATING MACHANISM

2.1. STONE CHIP TANK: 1 SET; AUTOMATIC CONTOL BY CYLINDER

(OPENED WHENEVER TILE SHEET FOUND AND CLOSED WHENEVER TILE SHEET PASSED).

2.2 CONVEYER MACHANISM: FOR STONE CHIP LOADING AND RECYCLING.

3. AUTOMATIC DUMPING MACHANISM

3. 1 DUMPING MACHANISM: THE MACHANISM CONTROLED BY CONVERTER AND APPROACH SWITCH WILL ERECT EACH TILE BOOTOM UP AND HEAD EADGE UP RESPECTIVELY SO THAT THE STONE CHIP S WILL COVER THE SURFACE EVENLY AND REMOVE EXTRA CHIPS.

3.2 RACK STRUCTURE: WELDED STRUCTURE OF STEEL PROFILES.

3.3 SPEED CONTROL: CONVERTER AND APPROACH SWITCH CONTROL.

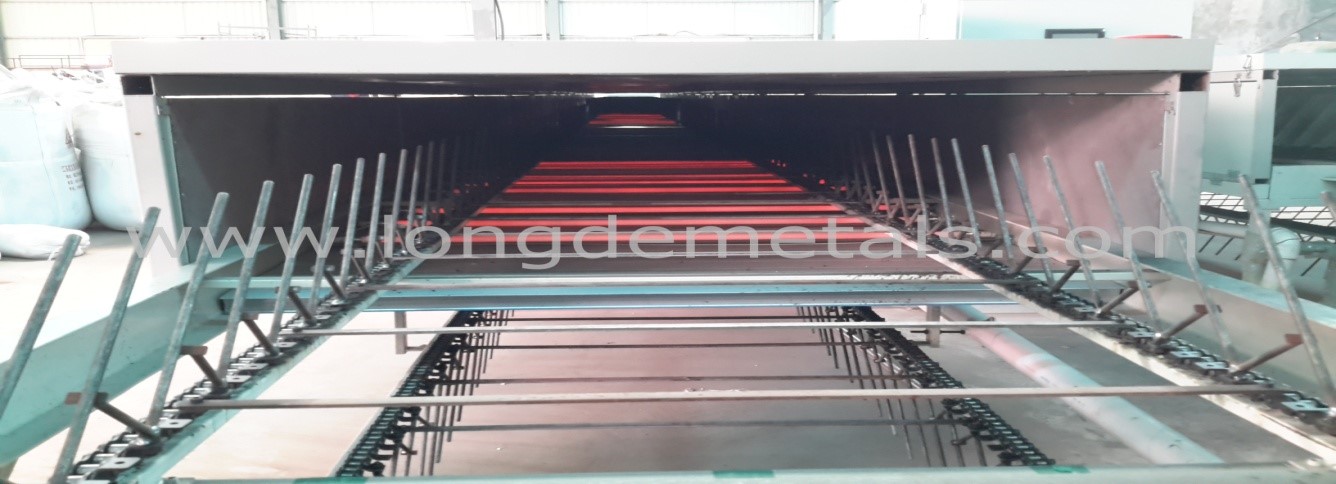

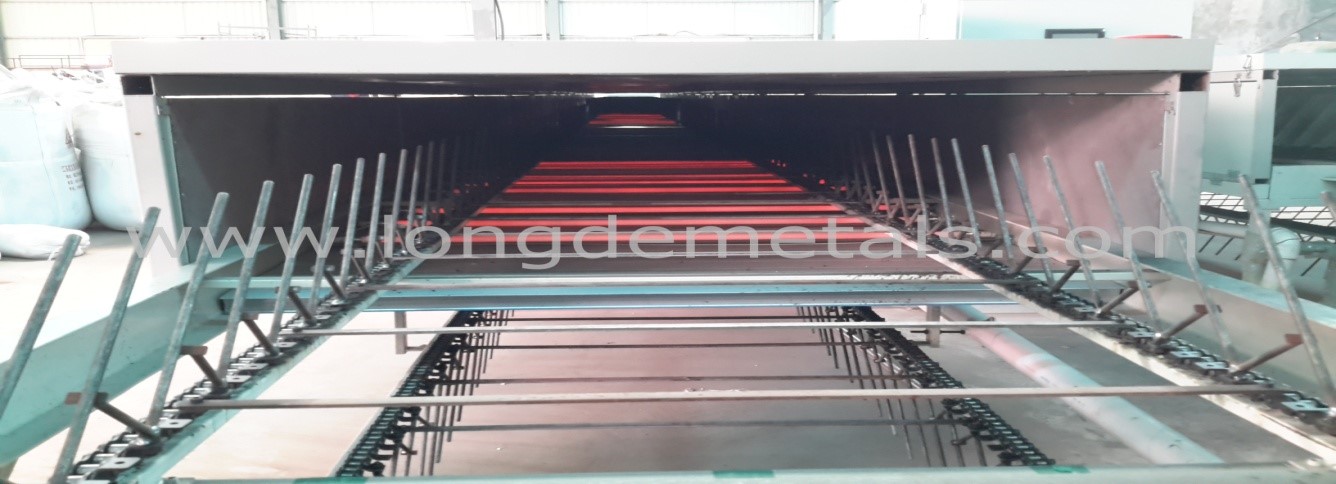

4. FIRST BAKE-DRY OVEN

4.1 SIZE: 30000*1650*1500 (L*W*H)

4.2 TRANSMISSION: CYCLO;

4.3 SPEED CONTROL: VVVF

4.4 OVEN STRUCTURE: 1.5mm STEEL FRAME THERMAL WALL WITH HIGH DENSITYHEAT RETAINING INSULATION FITTING

4.5. RACK STRUCTURE: WELDED STRUCTURE OF STEEL PROFILES

4.6. MODE OF HEATING a. INFRARED THERMAL TUBE HEATING.

b. GAS HEATING

4.7. TRANSMISSION: RACKS ON CHAINS

4.8 TEMPERATURE CONTROL: TED AUTOMATIC TEMPERATURE CONTROL ELEMENT;

5. SURFACE GLUE COATING CABINET

5.1 SIZE: 3000*850*2200((L*W*H)

5.2 RACK STRUCTURE: WELDED STRUCTURE OF STEEL PROFILES

5.3 TRANSMISSION RV FREQUENCY-ADHUSTABLE REDUCTION GEARS;

5.4 AUTOMATIC SPRAY GUN: 2 SETS OF ZPQ-1 AUTOMATIC HIGH-PRESURE SPRAY GUN

5.5 CONTROL MODE: APPROACH SWITCH CONTROL.

5.6 DEDUST APPLIANCE: ADSORPTION DUCT COLLECTOR;

6. SECOND BAKE-DRY OVEN

6.1 SIZE: 30000*1650*1600 mm (L*W*H)

6.2 TRANSMISSION: CYCLO;

6.3 SPEED CONTROL: VVVF

6.4 OVEN STRUCTURE: 1.2mm STEEL FRAME THERMAL WALL WITH HEAT RETAINING INSULATION FITTING

6.5 RACK STRUCTURE: WELDED STRUCTURE OF STEEL PROFILES

6.6 MODE OF HEATING: a. INFRARED THERMAL TUBES HEATING.

b. GAS HEATING .

6.7 TRANSMISSION: RACKS ON CHAINS

6.8 TEMPERATURE CONTROL: TED AUTOMATIC TEMPERATURE CONTROL ELEMENT .

7. PRODUCTIVE CAPACITY

7.1 IN GENERAL CONDITIONS, THE DESIGNED PRODUCTIVE CAPACITY IS 4000PCS/DAY(8 HOURS) 0R 1904 EFFECTIVE SQUARE METERS .

1.1 SIZE : 4000*1650*2000 (L*W*H)

1.2 RACK STRUCTURE: WELDED STRUCTURE OF STEEL PROFILES

1.3 Power: 380v/220v、50~60 Hz;

1.4 OPERATION SPEED: 4~10S/TILE

1.5 CONTROL: CVT AUTOMATIC CONTROL VIA PLC

1.6 BASE GLUE SPRAY: RECIPROCATING SPAY OPERATED BY PNEUMATIC AIRLESS SPAYER AND A STEPPING MOTOR

1.7 DEDUST APPLIANCE: ADSORPTION DUCT COLLECTOR.

2. AUTOMATIC STONE CHIP COATING MACHANISM

2.1. STONE CHIP TANK: 1 SET; AUTOMATIC CONTOL BY CYLINDER

(OPENED WHENEVER TILE SHEET FOUND AND CLOSED WHENEVER TILE SHEET PASSED).

2.2 CONVEYER MACHANISM: FOR STONE CHIP LOADING AND RECYCLING.

3. AUTOMATIC DUMPING MACHANISM

3. 1 DUMPING MACHANISM: THE MACHANISM CONTROLED BY CONVERTER AND APPROACH SWITCH WILL ERECT EACH TILE BOOTOM UP AND HEAD EADGE UP RESPECTIVELY SO THAT THE STONE CHIP S WILL COVER THE SURFACE EVENLY AND REMOVE EXTRA CHIPS.

3.2 RACK STRUCTURE: WELDED STRUCTURE OF STEEL PROFILES.

3.3 SPEED CONTROL: CONVERTER AND APPROACH SWITCH CONTROL.

4. FIRST BAKE-DRY OVEN

4.1 SIZE: 30000*1650*1500 (L*W*H)

4.2 TRANSMISSION: CYCLO;

4.3 SPEED CONTROL: VVVF

4.4 OVEN STRUCTURE: 1.5mm STEEL FRAME THERMAL WALL WITH HIGH DENSITYHEAT RETAINING INSULATION FITTING

4.5. RACK STRUCTURE: WELDED STRUCTURE OF STEEL PROFILES

4.6. MODE OF HEATING a. INFRARED THERMAL TUBE HEATING.

b. GAS HEATING

4.7. TRANSMISSION: RACKS ON CHAINS

4.8 TEMPERATURE CONTROL: TED AUTOMATIC TEMPERATURE CONTROL ELEMENT;

5. SURFACE GLUE COATING CABINET

5.1 SIZE: 3000*850*2200((L*W*H)

5.2 RACK STRUCTURE: WELDED STRUCTURE OF STEEL PROFILES

5.3 TRANSMISSION RV FREQUENCY-ADHUSTABLE REDUCTION GEARS;

5.4 AUTOMATIC SPRAY GUN: 2 SETS OF ZPQ-1 AUTOMATIC HIGH-PRESURE SPRAY GUN

5.5 CONTROL MODE: APPROACH SWITCH CONTROL.

5.6 DEDUST APPLIANCE: ADSORPTION DUCT COLLECTOR;

6. SECOND BAKE-DRY OVEN

6.1 SIZE: 30000*1650*1600 mm (L*W*H)

6.2 TRANSMISSION: CYCLO;

6.3 SPEED CONTROL: VVVF

6.4 OVEN STRUCTURE: 1.2mm STEEL FRAME THERMAL WALL WITH HEAT RETAINING INSULATION FITTING

6.5 RACK STRUCTURE: WELDED STRUCTURE OF STEEL PROFILES

6.6 MODE OF HEATING: a. INFRARED THERMAL TUBES HEATING.

b. GAS HEATING .

6.7 TRANSMISSION: RACKS ON CHAINS

6.8 TEMPERATURE CONTROL: TED AUTOMATIC TEMPERATURE CONTROL ELEMENT .

7. PRODUCTIVE CAPACITY

7.1 IN GENERAL CONDITIONS, THE DESIGNED PRODUCTIVE CAPACITY IS 4000PCS/DAY(8 HOURS) 0R 1904 EFFECTIVE SQUARE METERS .

Next Article: LD800 Rendering machine